Why GMP is Crucial for the Dietary Supplement Industry: The Cornerstone of Trustworthy Manufacturing

In today's health-conscious world, consumers are more discerning than ever when choosing dietary supplements. They focus not only on the efficacy of ingredients but also on product safety, purity, and consistency. Behind all this lies an indispensable guardian—GMP (Good Manufacturing Practices).

For dietary supplement manufacturers, GMP is not merely a set of cumbersome regulations, but an essential path to success and building brand reputation. Through standardized process control, it ensures that every batch of products meets pre-set quality standards, eliminating the risk of contamination, confusion, and errors at the source.

So, how do you translate GMP standards from theoretical provisions into solid and reliable production practices? The answer lies in choosing the right production equipment. This is precisely where the value of Shanghai Reliance Machinery lies—we are not only a provider of machinery but also your strategic partner in achieving GMP compliance and safeguarding product quality.

Core GMP Principles and Our Solutions

1. Preventing Contamination and Cross-Contamination – Creators of Sterile Environments

GMP Requirements: The production environment must be controlled, especially for liquids and probiotic products susceptible to microbial contamination. The risk of contamination by microorganisms, particles, and pyrogens must be minimized.

Reliance Solutions:

Sterile Vitamin Drops Filling Machine: Our filling system integrates a Class A laminar flow protection device, forming a sterile barrier in critical operating areas. Combined with a fully enclosed pipeline delivery system, it ensures that the entire process from the material tank to the final container is carried out in a sterile environment, perfectly handling products such as vitamin drops that have extremely high requirements for microbial control.

Laminar Flow Probiotic Filling Machine: Probiotic products have extremely stringent requirements for moisture and viable bacteria count stability. Our laminar flow filling machine provides a continuous and stable clean airflow (meeting Class A cleanliness standards) in the filling area, effectively isolating external contaminants and ensuring the purity and activity of probiotic powder during the filling process, safeguarding the shelf life of your products.

2. Ensuring Ingredient and Dosage Accuracy – A Practitioner of Precision and Consistency

GMP Requirements: The ingredients and content of each unit dose of product must be completely consistent with the label declaration, and batch-to-batch variations must be minimized.

Reliance Solution: Our fully automated filling machines utilize high-precision servo motors and metering pumps, achieving micro-level precision filling. Whether it's a viscous oil or a fine powder, we ensure precise content for every drop and every particle, eliminating waste, guaranteeing product efficacy, and ensuring your label declarations withstand any scrutiny.

3. Ensuring Traceability and Compliance Records – A Supporter of End-to-End Data-Driven Management

GMP Requirements: Every step of production should be clearly and accurately recorded, achieving end-to-end traceability from raw materials to finished products.

Reliance Solution: Our equipment seamlessly integrates with PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) systems, monitoring and recording key production data in real time, such as filling speed, metering settings, and output. This provides electronic evidence for your production batch records, greatly facilitating quality audits and product traceability, making compliance management easy and efficient.

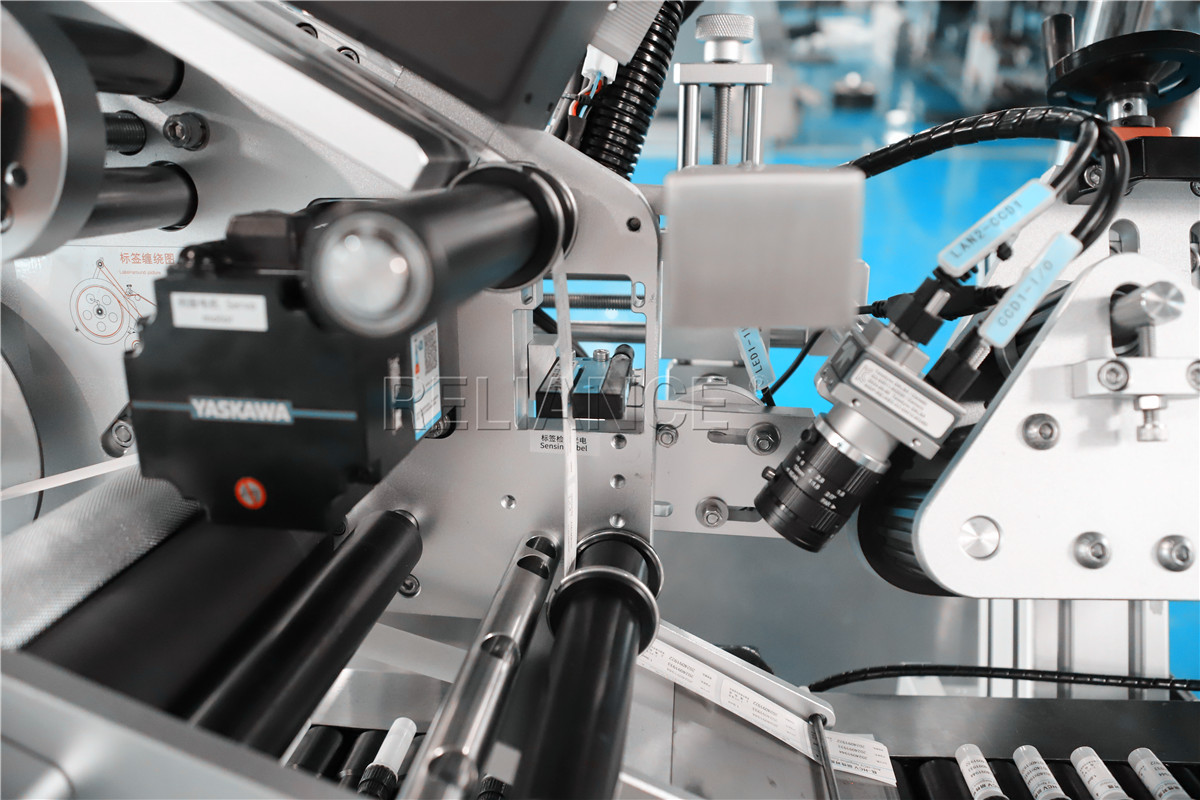

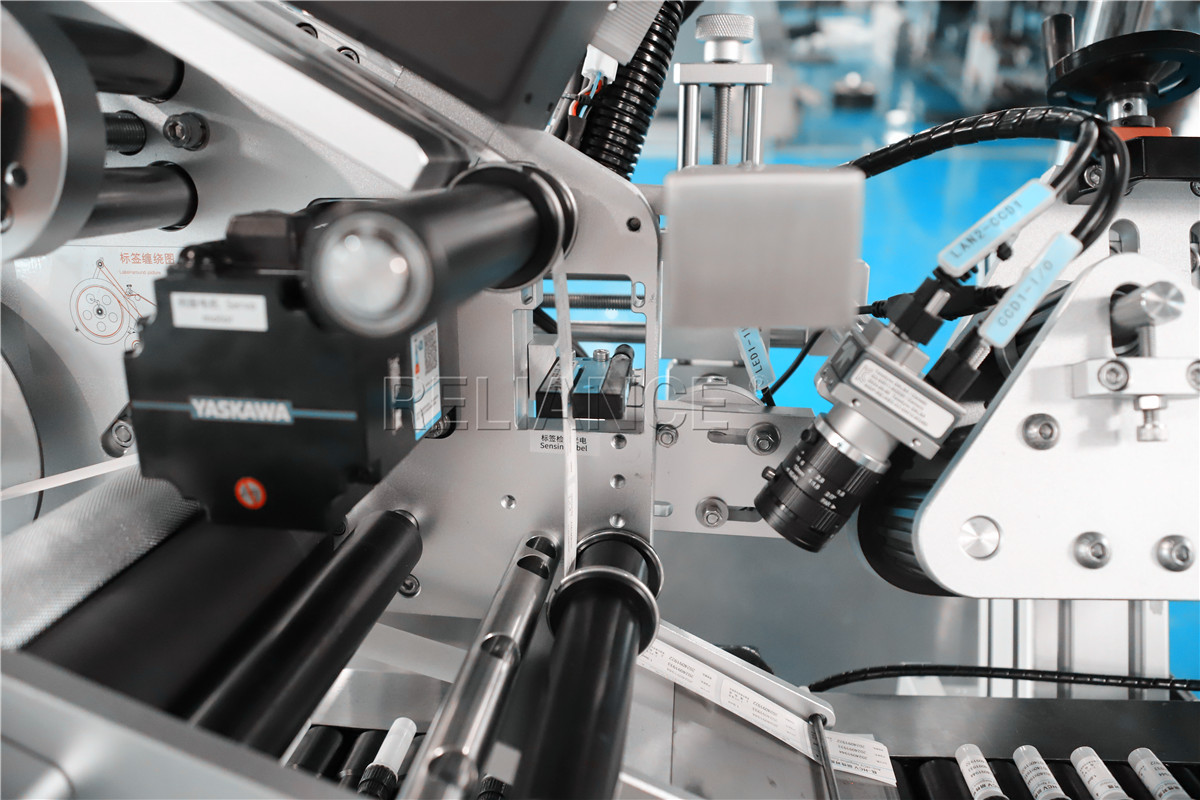

4. Correct Labeling and Packaging – Guardians of Brand Image

GMP Requirements: Product labels must be clear and accurate to prevent confusion such as mislabeling.

Reliance Solution: Our high-speed, high-precision labeling machines adapt to various bottle types and label materials, ensuring every label is flat, secure, and precisely positioned. This not only avoids costly recalls due to labeling errors but also directly enhances consumer trust and goodwill towards your brand through a clean and professional packaging appearance.

Choose Reliance – Choose Peace of Mind and Excellence

At Shanghai Reliance Machinery, we deeply understand the decisive impact of GMP on your business. Therefore, we create not just machines, but a complete GMP compliance solution.

Easy to Clean and Maintain (CIP/SIP Concept): Equipment is designed according to the principle of "easy to clean," reducing hygiene dead spots, minimizing the risk of cross-contamination, and shortening batch changeover time.

Compliant Materials: All parts in contact with materials are made of food- and pharmaceutical-grade materials such as 316L stainless steel, ensuring product compatibility.

Professional verification support: We can provide customers with comprehensive IQ/OQ (Installation/Operation Qualification) documentation support to help you quickly pass GMP certification audits.